A Practical Guide for Healthcare Engineering Systems in Day Procedure Centres

Since 3 February 2023, the requirements of specific healthcare engineering systems (i.e. electrical installation, specialized ventilation system and medical gas supplies) of day procedure centres have formed part of the regulatory standard in the Code of Practice for Day Procedure Centres. As a transitional arrangement, such requirements will take effect from 1 January 2028.

Prospective applicants of day procedure centre licences and licensees of existing facilities should engage the engineering service providers so as to ensure that all relevant requirements pertaining to the healthcare engineering systems are adhered to.

To this end, this office has compiled a practical guide, associated pamphlet and frequently asked questions for the trade practitioners and stakeholders, such as licensees of day procedure centre, registered professional engineers, consulting engineers and healthcare engineering installation contractors. These publications, though not exhaustive, outline the key points to note regarding the design, installation, operation and maintenance of healthcare engineering systems of day procedure centres and other useful information, including examples of DOs and DON'Ts for compliance with the regulatory requirements.

The following guide is for general reference and information purposes only, and should be read in conjunction with the latest version of the Code of Practice for Day Procedure Centres, other applicable ordinances, regulations and codes.

- Engage competent service providers (including a registered professional engineer) with relevant qualification and experience since early design stage to carry out design, installation and certification of electrical installations for critical care areas.

- Follow the requirements of internationally acceptable healthcare standards, e.g. Health Technical Memorandum (HTM) 06-01 (2017 edition) - Electrical services supply and distribution, or equivalent, as set out in the Code to carry out design and installation of the electrical installations for critical care areas.

- Stocktake all the installations and equipment that require back-up power supplies, e.g. critical medical equipment, operating lamp, and all general lighting installations in operating room and recovery area.

- Determine the back-up time required from operational point of view for sizing back-up power supplies.

- Prepare summary of the healthcare electrical standard(s) / code(s) by critical care areas, schematic diagram and layout plan of the electrical installations before carrying out on-site installation and statutory submission. (Please refer to the document checklist PHF 212 for details)

- Ensure that all the electrical installation related documents are properly kept and available on site, e.g. as-fitted electrical drawings, power demand calculation. (Please refer to the document checklist PHF 216 for details)

- Record all the maintenance activities properly, e.g. maintain a logbook for regular preventive maintenance and repair work.

| ✓ |

Design and install suitable back-up power supplies for critical care area, e.g. uninterruptible power supplies (UPS) system. |

|

| ✓ |

Provide proper labelling for the socket outlets with back-up power supplies in critical care area. |

|

| ✓ |

Provide uninterruptible power supplies (UPS) system or built-in batteries for operating lamp in operation room. |

|

| ✓ |

Provide back-up power supplies or secondary battery of light fitting for all general lighting installations in critical care area. |

|

| ✓ |

Design and install isolated power supply (IPS) system for life critical medical device, e.g. anaesthetic machine with ventilator for life support when general anaesthesia or major regional anaesthesia is performed. |

|

| ✘ |

Provide back-up power supply for a critical care area by emergency generator only and without due consideration of the need for continuous operation of critical medical devices therein. (Note: power supply from emergency generator are automatically available within 15 seconds upon loss of normal electrical power supply) |

| ✘ |

Provide back-up power supplies only for part of general lightings in critical care area. |

| ✘ |

Provide normal power supply only for recovery area. (Note: recovery area is defined as a critical care area, where back up power supplies are required) |

| ✘ |

Follow the requirements of outdated international healthcare engineering standards. |

| ✘ |

Prepare a schematic diagram which does not tally with the corresponding layout plans. |

Specialized Ventilation Systems

- Engage competent service providers (including a registered professional engineer) with relevant qualification and experience since early design stage to carry out design, installation and certification of specialized ventilation systems.

- Follow the requirements of internationally acceptable healthcare standards, e.g. ANSI/ASHRAE/ASHE Standard 170-2021 – Ventilation of Health Care Facilities, or Health Technical Memorandum (HTM) 03-01 (2021 edition) – Specialised ventilation for healthcare premises, or equivalent, as set out in the Code to carry out design and installation of the specialized ventilation systems.

- Coordinate with building facility management team in early stage to ensure the availability of required infrastructure, e.g. ensure sufficient fresh air supply to achieve the minimum outdoor air change rate for operating room.

- Ensure sufficient space and headroom in an operating room for installation of specialized ventilation systems, including all the required components such as low sidewall return or exhaust grilles, supply diffuser array with unidirectional and downwards flow pattern.

- Prepare summary of the healthcare ventilation and air-conditioning standard(s) / code(s) by specialized ventilation systems, schematic diagram and layout plan of the specialized ventilation systems before carrying out on-site installation and statutory submission. (Please refer to the document checklist PHF 212 for details)

- Ensure that all the specialized ventilation system related documents are properly kept and available on site, e.g. as-fitted ventilation system drawings, air change rates calculation. (Please refer to the document checklist PHF 216 for details)

- Record all the maintenance activities properly, e.g. maintain a logbook for regular preventive maintenance and repair work.

| ✓ |

Provide at least two low sidewall return or exhaust grilles spaced at opposite corners in an operating room. |

|

| ✓ |

Select suitable primary supply diffuser array with unidirectional and downwards flow pattern in an operation room. |

|

| ✓ |

Provide individual temperature control for an operating room. |

|

| ✓ |

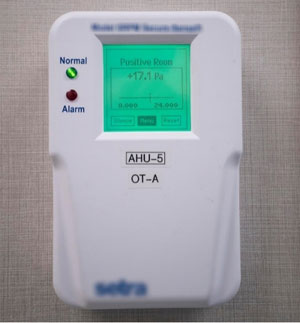

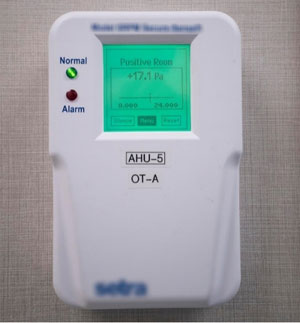

Monitor pressure gradient at an operating room with the use of appropriate monitoring device, e.g. real-time differential pressure meter. |

|

| ✘ |

Provide only middle/high level return or exhaust air grilles in an operating room. |

|

| ✘ |

Select primary supply diffuser array with multi-directional flow pattern in an operation room. |

|

| ✘ |

Install air-conditioning units inside an operating room, causing risk of water seepage, bacterial growth and difficulties in future equipment maintenance. |

|

| ✘ |

Design a single specialized ventilation system serving multiple operating rooms without individual room temperature control. |

| ✘ |

Prepare a schematic diagram that does not tally with the corresponding layout plan. |

| ✘ |

Follow the requirements of outdated international healthcare engineering standards. |

Medical Gas Pipeline Systems

- Engage competent service providers (including a registered professional engineer) with relevant qualification and experience since early design stage to carry out design, installation and certification of medical gas pipeline systems.

- Follow the requirements of internationally acceptable healthcare engineering standards, e.g. Health Technical Memorandum (HTM) 02-01 (2006 edition) – Medical gas pipeline systems, or equivalent, as set out in the Code to carry out design and installation of the medical gas pipeline systems.

- Ensure sufficient space to locate multiple sources of piped medical gas supplies, namely primary, secondary and reserve, and their associated gas manifold(s).

- Prepare summary of the medical gas pipeline system standard(s) / code(s) by service areas, schematic diagram and layout plan of the medical gas pipeline systems before carrying out on-site installation and statutory submission. (Please refer to the document checklist PHF 212 for details)

- Ensure that all the medical gas pipeline system (MGPS) related documents are properly kept and available on site, e.g. as-fitted MGPS drawings, diversified gas demand calculation. (Please refer to the document checklist PHF 216 for details)

- Record all the maintenance activities properly, e.g. maintain a logbook for regular gas pressure test and repair work.

| ✓ |

Ensure all medical gas pipeline system (MGPS) comprising of multiple sources of supply, namely primary, secondary and reserve, where fully-automatic manifold is used (the photo displays a kind of arrangement for primary source of medical gas supplies through gas cylinders). |

|

| ✓ |

Provide back-up power supplies to medical gas pipeline system plants and equipment. |

|

| ✓ |

Provide gas test point for medical gas pipeline system. |

|

| ✓ |

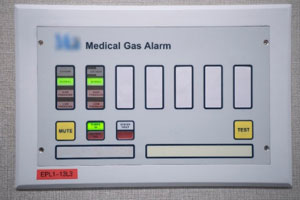

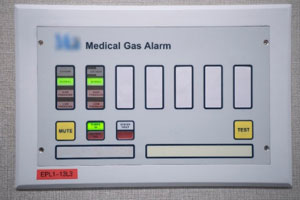

Install warning and alarm system to monitor the safe and efficient operation of the medical gas pipeline systems. |

|

| ✓ |

Install valve set (e.g. area valve service unit (AVSU)) for the medical gas pipeline system for maintenance / repair purposes. |

|

| ✓ |

Where anaesthetic gas scavenging disposal system (AGSS) is installed, its discharge is placed at a suitable location to minimize the recirculation of discharged air back into the building. |

|

| ✓ |

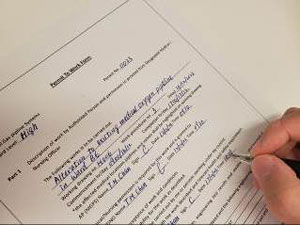

Appoint an authorized person in writing by the Chief Medical Executive (CME) of the Facility for supervising the maintenance, repair and alteration work of the medical gas pipeline systems. |

|

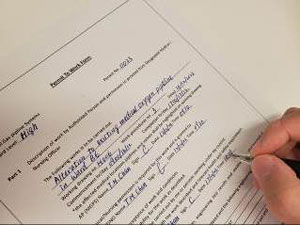

| ✓ |

Govern all works on the existing medical gas pipeline systems by a safety management system, e.g. a permit-to-work form. |

|

| ✘ |

Provide only single or inadequate sources of medical gas supplies for the medical gas pipeline systems. |

| ✘ |

Estimate the required quantity and capacity of medical gas cylinder without adequate justification in accordance with the internationally acceptable standard, operational policy and contingency plan of the facility. |

| ✘ |

Implement a permit-to-work system only by a contract-out service agent without supervision and authorization of facility management personnel. |

|

| ✘ |

Follow the requirements of outdated international healthcare engineering standards. |

| ✘ |

Prepare a schematic diagram that does not tally with the corresponding layout plans. |

The electronic pamphlet with practical information is also available for download (Traditional Chinese version available only).

.jpg)

Pamphlet for Healthcare Engineering Systems in Day Procedure Centre

.jpg)